Until recently, 3D printing was largely relegated to prototyping and small-scale projects

due to fundamental limitations—slowness and an inability to generate objects with adequate

mechanical strength and thermal properties that would entail widespread, durable utility. A

limited range of materials also hindered the ability to make parts comparable to injection molded

parts.

Rethinking the basic physics and chemistry, we invented Digital Light SynthesisTM (DLS)

to address these longstanding major drawbacks. Introduced on the cover of Science [2015, 347,

1349], DLS is now transforming how parts are manufactured in industries including automotive,

footwear, and medicine. Its revolutionary nature as a digital manufacturing technology creates

possibilities for market-shifting transformations with significant economic and environmental

implications.

This lecture will discuss opportunities and challenges associated with launching a

subscription-based digital manufacturing breakthrough. Digital transformation is easy for

software-centric products and businesses but much harder for products and businesses in the

physical world. Greater momentum now exists for this digital transformation due to the

technological revolution in additive manufacturing (3D printing) and the urgency for greater

dynamism and adaptability in supply chains—with the COVID-19 pandemic serving as the

clearest example of the economic and societal challenges that occur when supply chains are

disrupted on a grand scale. With this transformation, additive manufacturing will enable localfor-

local production; continuous digital thread and the smart factory; scaling personalized

products (e.g. perfectly fitting prosthetics, surgical implants from advanced imaging modalities);

rapid product introductions; and end of inventory with just-in-time production—stimulating

greater supply chain dynamism and adaptability.

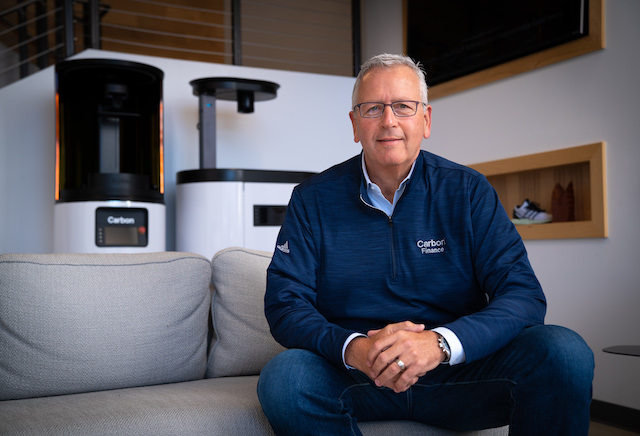

Speaker:

Institution:

Location: